Last Updated: March 28, 2025

Are you struggling with Amazon global supply chain challenges? Learn about them in this guide, along with multiple ways to solve and prevent them from disrupting your business.

Handling global supply chain challenges is essential for Amazon sellers aiming to ensure consistent operations and meet customer expectations. Issues such as shipping delays, rising costs, inventory management, and quality control each present their own set of difficulties.

Both Fulfillment by Amazon (FBA) and Fulfillment by Merchant (FBM) sellers need effective strategies to manage these challenges. This article addresses the common Amazon supply chain issues faced by sellers and offers practical solutions for both FBA and FBM models.

From tackling delays and controlling shipping expenses to optimizing inventory and ensuring product quality, this guide provides actionable advice to help you effectively manage these complexities and maintain a competitive edge in the Amazon marketplace.

Table of Contents

1. Shipping Delays

FBA Sellers

Shipping delays, caused by port congestion, customs, logistics disruptions, or global events, impact FBA sellers by affecting inventory and customer satisfaction. A major example of this is the labor strikes at Amazon warehouses and U.S. ports, which have disrupted supply chains.

Solutions:

- Monitor Amazon’s Performance Metrics: Regularly check performance metrics and shipping notifications to spot potential delays early and manage them proactively.

- Plan for Seasonal Variations: Adjust inventory levels for peak seasons to prevent stockouts and reduce the impact of delays.

- Utilize Amazon’s Reporting Tools: Analyze shipping performance data with Amazon’s tools to identify patterns and address recurring issues.

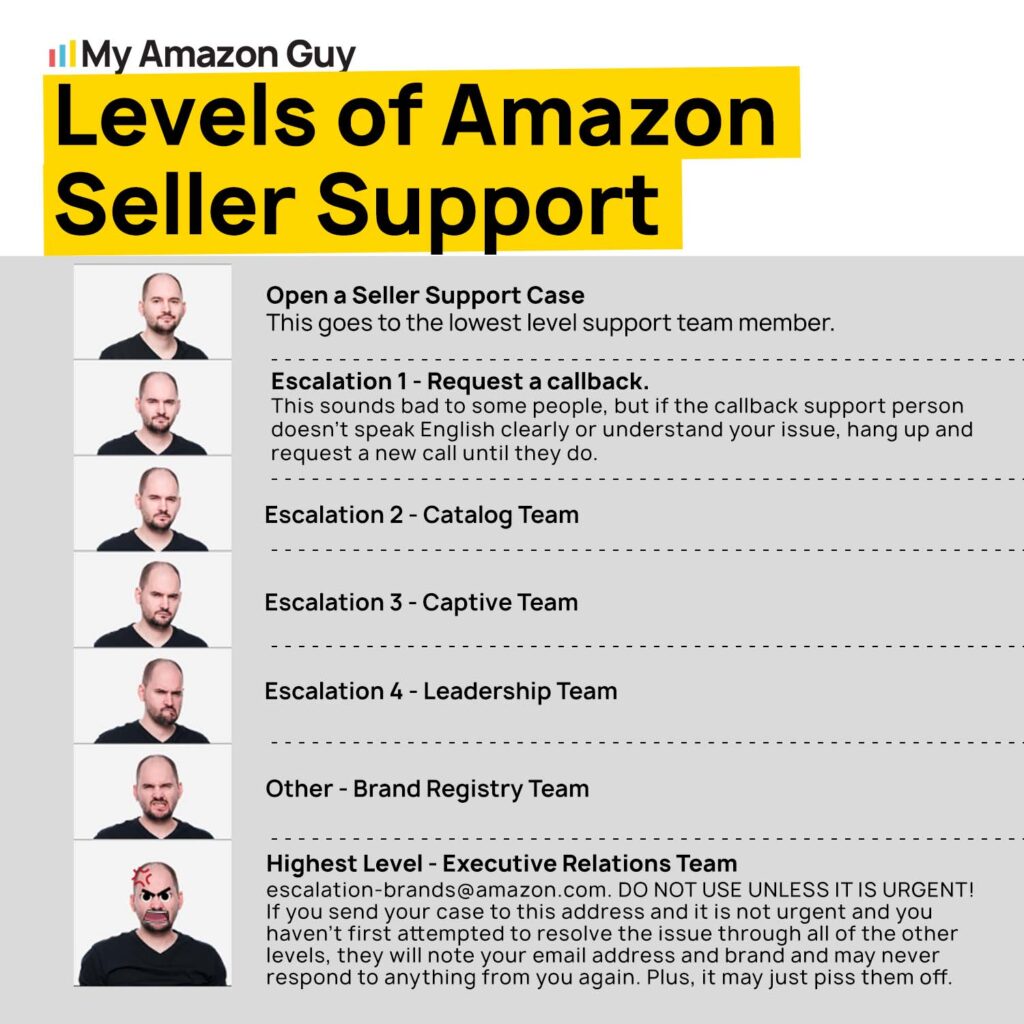

- Communicate with Amazon: Contact Amazon Seller Support if delays are frequent. Reporting issues helps Amazon address them and improve shipping performance.

FBM Sellers

For FBM sellers, shipping delays can be caused by carrier issues, customs, supply chain disruptions, and weather conditions. Unlike FBA sellers, FBM sellers are responsible for their fulfillment, making them more vulnerable to logistical breakdowns and delivery slowdowns.

Solutions:

- Diversify Logistics Partners: Partner with multiple carriers to avoid relying on one provider and ensure alternatives if delays occur.

- Implement Advanced Tracking Systems: Use real-time tracking systems to monitor shipments, anticipate delays, and communicate with shoppers effectively.

- Strengthen Carrier Relationships: Build strong relationships with logistics partners for better communication and quicker issue resolution.

- Plan for Contingencies: Develop backup plans for common issues like carrier delays, including alternative carriers and shipping options.

2. Rising Shipping Costs

FBA Sellers

FBA sellers face higher shipping costs due to carrier rate increases, Amazon fees, peak season demand, and inflation, impacting profit margins. Although Amazon announced it will not raise FBA fulfillment fees for standard-size products, sellers still face rising storage fees, fuel surcharges, and peak season costs.

Solutions:

- Optimize Inventory Management: Use Amazon’s tools to manage inventory placement and reduce storage fees, minimizing holding costs.

- Utilize Amazon’s Shipping Discounts: Use Amazon’s discounted shipping rates to reduce costs for FBA orders.

- Review and Adjust Pricing Strategies: Adjust product prices or promotions to offset increased shipping costs and maintain profit margins.

- Monitor Fee Changes: Stay updated on fee changes and adjust inventory and shipping strategies to adapt to any increases.

FBM Sellers

FBM sellers can encounter high shipping costs due to increased carrier rates, international shipping expenses, rising packaging and handling costs, and fluctuating fuel prices. This issue can affect pricing strategies and profitability.

Solutions:

- Negotiate with Carriers: Build relationships with carriers and negotiate rates for better pricing. Regularly review and update contracts for optimal rates.

- Optimize Packaging: Use cost-effective packaging to cut material and shipping fees, saving on transportation and handling.

- Explore Alternative Shipping Solutions: Evaluate different shipping methods or carriers for lower rates or better service.

- Adjust Shipping Policies: Update shipping policies to manage costs, such as setting minimum order requirements for free shipping or offering tiered options.

3. Inventory Management

FBA Sellers

FBA sellers encounter challenges in maintaining optimal stock levels due to demand fluctuations, Amazon’s inventory limits, fulfillment center distribution inefficiencies, and the complexities of multi-channel fulfillment. Limited FBA capacity during peak seasons like Black Friday and Cyber Monday can lead to stockouts, resulting in lost sales and revenue.

Solutions:

- Use Capacity Manager: Amazon’s tool allows sellers to request additional storage space when needed.

- Strategic Bidding: Sellers can bid for extra space by setting a maximum reservation fee based on their budget and demand.

- Analyze Historical Data: Reviewing past reservation fees helps sellers make informed decisions and avoid overpaying.

- Leverage Amazon’s Calculator: This tool estimates performance credits and helps sellers determine appropriate reservation fees.

- Plan Expiration Dates Wisely: Sellers should align storage requests with restocking timelines to avoid charges for unused space.

FBM Sellers

FBM sellers often struggle with inventory management due to supply chain disruptions, manual tracking, storage limitations, and fluctuating customer demand. Without Amazon’s built-in tracking, they rely on independent inventory systems to monitor stock levels, forecast demand, and avoid overselling.

Solutions:

- Use Advanced Inventory Management Software: Invest in software to automate tracking, forecasting, and order fulfillment for efficient stock management.

- Establish Reliable Supplier Relationships: Build strong supplier relationships for consistent delivery and effective communication to prevent disruptions.

- Optimize Storage Solutions: Find cost-effective storage options to maximize space and efficiency, considering third-party logistics if needed.

- Monitor and Adapt to Demand Fluctuations: Use data analytics to track and adjust inventory levels based on changing customer demand and sales trends.

4. Supplier Reliability

FBA Sellers

FBA sellers who source products from platforms like Alibaba often face supply chain disruptions, especially when importing from countries like China. Supplier performance variability, reliance on single suppliers, supply shortages, and quality control issues can impact the reliability of inventory supplied to Amazon’s fulfillment centers.

Solutions:

- Diversify Suppliers: Work with multiple suppliers to reduce risk and ensure a more reliable supply chain.

- Establish Clear Contracts and Agreements: Use detailed contracts to set expectations, quality standards, and delivery schedules with suppliers.

- Conduct Supplier Audits: Regularly audit suppliers to ensure they meet quality and reliability standards, addressing issues before they impact inventory.

- Monitor Supplier Performance: Track supplier reliability and quality with performance metrics like on-time delivery and defect rates.

FBM Sellers

FBM sellers, like FBA sellers, face supplier reliability challenges, especially when sourcing from third-party manufacturers overseas. However, since they handle warehousing and shipping themselves, any delays or quality issues directly impact their fulfillment and performance metrics.

Solutions:

- Establish Backup Suppliers: Build relationships with backup suppliers to quickly source products if primary suppliers face issues.

- Improve Supplier Communication: Use technology for real-time updates and clear communication to address issues and avoid delays.

- Implement Contingency Plans: Develop plans for alternative sourcing and managing disruptions to ensure business continuity.

- Use Technology for Better Visibility: Employ supply chain management software to track orders, manage inventory, and identify potential issues early.

5. Customs and Compliance Issues

FBA Sellers

International trade involves complex customs regulations, requiring accurate documentation and compliance with product requirements. Sudden tariff increases, like those on Chinese imports, can raise costs significantly, forcing sellers to either absorb the expense or find alternative suppliers, which adds logistical challenges.

Solutions:

- Leverage Amazon’s Global Selling Tools: Use Amazon’s tools to streamline customs processes and ensure international compliance.

- Stay Informed on Regulations: Keep updated on customs regulations and trade policies, adapting compliance strategies as needed.

- Utilize Amazon’s Compliance Programs: Use Amazon’s compliance programs, like Brand Registry, to meet regulatory requirements and protect listings.

- Conduct Regular Compliance Audits: Regularly audit your accounts as well as customs and compliance processes to identify and address potential issues.

FBM Sellers

FBM sellers face additional challenges with cross-border logistics since they handle customs clearance themselves, increasing the risk of delays from incorrect documentation or regulatory changes. FBM sellers must also handle customs fees, tariffs, and compliance requirements independently, which can lead to unexpected costs and shipment disruptions.

Solutions:

- Partner with Reliable Customs Agents: Collaborate with experienced customs agents to manage processes efficiently and reduce delays.

- Ensure Accurate Documentation: Verify all customs paperwork to avoid delays and additional costs.

- Plan for Tariffs and Duties: Factor in potential tariffs and duties in your pricing to maintain profitability and stay updated on trade policy changes.

- Develop Compliance Procedures: Create clear procedures to ensure adherence to customs regulations and product standards.

6. Forecasting and Demand Planning

FBA Sellers

FBA sellers rely on accurate demand forecasting to avoid stockouts or excess inventory, but challenges arise due to Amazon’s storage fees and restock limits. Seasonal demand shifts, incomplete sales data, and restrictions on inventory replenishment can make it difficult to predict and maintain optimal stock levels, leading to lost sales or increased storage costs.

Solutions:

- Utilize Amazon’s Forecasting Tools: Use Amazon’s tools and data to predict demand based on historical sales and trends.

- Implement Advanced Analytics: Apply analytics and machine learning to enhance forecasting accuracy by analyzing diverse data sources.

- Monitor Market Trends: Stay updated on market trends and consumer behavior to adjust inventory planning accordingly.

- Collaborate with Amazon’s Demand Planning Team: Work with Amazon’s team to align inventory strategies and gain insights into demand patterns.

Need help in understanding Amazon’s Demand Forecasting Tool? Watch our Amazon agency’s video guide to learn more.

What You Will Learn:

- For Current Sellers: Discover strategies to optimize inventory based on past performance and Amazon’s tools.

- For New Sellers: Learn how to estimate initial inventory needs and adjust forecasts with early sales data.

- General Insights: Get tips on planning inventory effectively to avoid common pitfalls.

FBM Sellers

FBM sellers struggle with demand forecasting because they lack Amazon’s inventory performance data and must independently manage stock levels and shipping logistics. For instance, a seller handling holiday-season demand might underestimate peak sales, leading to stockouts and missed revenue, or overestimate demand, resulting in excess inventory and higher storage costs.

Solutions:

- Invest in Demand Planning Software: Use software to analyze sales data and market trends for better forecast accuracy.

- Analyze Sales Patterns: Regularly review sales data and consumer behavior to refine demand forecasts.

- Build Strong Supplier Relationships: Maintain good relationships with suppliers to quickly adjust inventory levels based on demand changes.

- Monitor External Factors: Track economic conditions, industry trends, and competition to adjust inventory planning accordingly.

7. Supply Chain Visibility

FBA Sellers

FBA sellers face limited supply chain visibility because Amazon controls warehousing and fulfillment, restricting access to real-time inventory movement and shipment status. As an example, if a shipment is delayed at an Amazon fulfillment center, sellers may not receive timely updates, making it difficult to adjust stock levels or inform customers, leading to potential stockouts or order cancellations.

Solutions:

- Use Amazon’s Reporting Tools: Utilize Amazon’s tools to track inventory levels and performance metrics within fulfillment centers.

- Implement Inventory Management Systems: Employ advanced systems for real-time inventory tracking and reporting, integrated with Amazon’s platform.

- Regularly Review Performance Reports: Analyze performance reports to spot trends, issues, and improvement areas for better inventory and fulfillment management.

- Collaborate with Amazon Support: Work with Amazon support to resolve visibility issues and gain deeper insights into your supply chain operations.

FBM Sellers

FBM sellers struggle with supply chain visibility because they often rely on third-party carriers and multiple suppliers with varying response times. So if a supplier delays a shipment, an FBM seller may not receive immediate updates, making it difficult to adjust stock levels or notify customers, potentially leading to order cancellations or negative reviews.

Solutions:

- Adopt Supply Chain Management Software: Use software for comprehensive tracking and visibility to streamline operations.

- Utilize Real-Time Tracking Solutions: Invest in real-time tracking for better insights into order status and inventory levels.

- Centralize Data Sources: Integrate data from all sources into one platform for a unified view of the supply chain.

- Monitor and Analyze Supply Chain Performance: Regularly check performance metrics to spot trends and optimize operations.

8. Quality Control

FBA Sellers

Regardless of how products are sourced, FBA sellers must meet Amazon’s strict quality standards while having little control over how items are stored, packed, and shipped in fulfillment centers. This can lead to issues like damaged goods, improper packaging, or customer complaints, impacting seller performance.

Solutions:

- Establish Strict Quality Standards: Set and enforce clear quality standards with suppliers to ensure consistency.

- Utilize Amazon’s Quality Assurance Programs: Use Amazon’s quality programs to meet their standards and ensure product compliance.

- Monitor Product Reviews and Feedback: Check customer reviews to spot and address quality issues.

- Engage with Amazon’s Fulfillment Centers: Collaborate with fulfillment centers to ensure proper handling and storage.

FBM Sellers

FBM sellers must handle quality control and manage returns on their own, which takes time and resources. They also rely on suppliers for product quality and customer feedback to catch quality issues.

Solutions:

- Implement Rigorous Quality Control Procedures: Set up strict quality checks for products at multiple stages before shipping.

- Regularly Audit Suppliers: Perform frequent supplier audits to ensure quality standards are met.

- Respond to Customer Feedback: Monitor and address customer feedback to resolve quality issues and improve products.

- Train Staff on Quality Standards: Educate staff on quality standards and procedures to ensure compliance and effective quality control.

9. Technological Integration

FBA Sellers

FBA sellers must integrate their inventory, order management, and reporting systems with Amazon, but frequent platform updates and API limitations can cause data discrepancies. The lack of customization options also makes it difficult to tailor systems to specific business needs.

Solutions:

- Utilize Amazon’s Integration Tools: Use Amazon’s tools and APIs for better data synchronization with third-party systems.

- Invest in Compatible Software: Select software designed to integrate seamlessly with Amazon’s systems, such as Helium 10 and Jungle Scout.

- Monitor and Adapt to Updates: Keep up with changes to Amazon’s platform and adjust integrations as needed.

- Work with Integration Specialists: Consult with experts to ensure smooth integration and resolve technical issues.

FBM Sellers

FBM sellers often face compatibility issues between their inventory management or shipping software and Amazon’s system, forcing them to manually input data, which increases the risk of errors. What’s more, many advanced automation tools are designed for larger sellers, making them expensive or impractical for smaller businesses.

Solutions:

- Adopt Comprehensive Software Solutions: Implement integrated software that covers inventory management, order processing, and customer service with strong integration capabilities.

- Leverage Integration Platforms: Use platforms that connect various systems and tools to improve efficiency and bridge gaps between technologies.

- Provide Training and Support: Offer training and ongoing support for your team to optimize the use of technology solutions and address integration issues effectively.

- Consider Outsourcing Integration: If in-house integration is complex, outsource a full-service Amazon agency that can manage and execute integration projects efficiently.

10. Geopolitical Issues

FBA Sellers

FBA sellers depend on stable international supply chains, but geopolitical shifts can disrupt sourcing and fulfillment. Since Amazon controls the fulfillment process, sellers have little flexibility to adapt quickly to these changes, often leading to stockouts or higher costs.

Solutions:

- Diversify Supply Sources: Establish relationships with multiple suppliers to reduce the risk of disruptions due to political instability or trade policy changes in any single region.

- Stay Informed on Trade Policies: Regularly monitor global trade policies and regulatory changes to anticipate their impact on your supply chain and adjust your strategies accordingly.

- Develop Contingency Plans: Prepare contingency plans for various geopolitical scenarios, including alternative sourcing and logistics strategies, to minimize the impact of potential disruptions.

- Optimize Inventory Management: Maintain optimal inventory levels to mitigate risks from geopolitical events and avoid stockouts by buffering against potential supply chain disruptions.

FBM Sellers

FBM sellers must handle geopolitical risks that affect direct shipping routes and last-mile delivery, often without Amazon’s logistical support. For example, sudden import restrictions on certain materials could force an FBM seller to quickly find alternative suppliers or adjust fulfillment timelines, leading to other problems

Solutions:

- Diversify Suppliers and Partners: Build relationships with multiple suppliers and logistics partners to lessen reliance on any single source and reduce risk from geopolitical disruptions.

- Hedge Currency Risks: Use financial instruments like forward contracts or diversify your currency exposure to protect your profit margins from volatility due to geopolitical factors.

- Monitor Political Developments: Stay updated on geopolitical events that could impact your supply chain by following news and expert analysis, allowing you to anticipate and respond to potential disruptions.

- Adjust Sourcing and Logistics Strategies: Remain adaptable in your sourcing and logistics strategies by exploring alternative options and routes to mitigate the effects of geopolitical risks.

Industry-Specific Amazon Supply Chain Challenges

FBA and FBM sellers face distinct supply chain challenges, requiring different strategies to manage inventory, fulfillment, and logistics. However, beyond these differences, industry-specific issues also play a major role since demand forecasting, inventory management, and regulatory requirements can vary significantly by sector.

1. Healthcare

Selling healthcare products on Amazon is challenging because of strict regulations, stock shortages, and tracking issues like expired or recalled items. Many sellers also struggle with keeping the right inventory levels, which can lead to running out of stock or overstocking.

To fix this, sellers should use real-time inventory tracking and work with reliable suppliers that follow Amazon’s rules. Having backup suppliers and using 3PL providers specializing in healthcare distribution can also help mitigate risks and ensure consistent product availability.

2. Retail

Amazon retail sellers struggle with supply chain issues like unpredictable demand, seasonal inventory shifts, and outdated tracking systems. This often leads to overstocking, stockouts, and lost sales.

Using real-time sales data and demand forecasting tools helps sellers adjust inventory faster. Working with reliable suppliers and having backup fulfillment options can also prevent stock problems.

3. Manufacturing and Automotive

Manufacturing and automotive sellers on Amazon face major supply chain issues like delays in getting parts, inconsistent inventory data, and supplier bottlenecks. These problems make it hard to track stock levels accurately, leading to missed sales or excess inventory.

Fixing these issues requires better inventory tracking tools that sync data across suppliers and warehouses in real time. Building relationships with multiple suppliers and securing backup shipping options can also help avoid disruptions.

FAQs About Amazon Global Supply Chain

What is Amazon’s supply chain?

Amazon’s supply chain is a global network of suppliers, warehouses, fulfillment centers, and logistics partners that work together to store, process, and ship products to customers. It includes both Amazon-owned inventory and third-party seller fulfillment.

How does Amazon’s supply chain work?

Amazon’s supply chain operates through advanced logistics, automation, and real-time inventory tracking. It ensures fast delivery by using strategically located fulfillment centers, optimized shipping routes, and partnerships with carriers.

Why is Amazon’s supply chain so successful?

Amazon’s supply chain is efficient because of its advanced technology, strong supplier relationships, and massive fulfillment network. Its ability to predict demand and streamline operations allows for fast shipping and low costs.

Conquering Amazon Supply Chain Challenges: Strategies for Success

Effectively managing global supply chain challenges is crucial for Amazon sellers to thrive in the e-commerce sector. By focusing on strategies such as diversifying suppliers, optimizing existing inventory, and enhancing warehouse operations, sellers can address common issues like shipping delays, rising costs, and quality control problems.

FBA and FBM sellers face different obstacles, but using the right strategies can boost efficiency and reduce risks. Keeping up with industry changes and using technology will make it easier to manage these challenges.

With a strong supply chain strategy, your business can navigate obstacles and continue to grow in the competitive e-commerce market.

Need help with your Amazon business? Contact our Amazon agency today!